PSA Nitrogen Gas Generators

500000 INR/Unit

Product Details:

- Product Type PSA Nitrogen Gas Generator

- General Use Industrial/Commercial Nitrogen Production

- Material Mild Steel / Stainless Steel

- Type Pressure Swing Adsorption (PSA)

- Capacity 5 1000 Nm/hr

- Purity(%) 95% 99.999%

- Production Rate Continuous

- Click to View more

X

PSA Nitrogen Gas Generators Price And Quantity

- 1 Unit

- 500000 INR/Unit

PSA Nitrogen Gas Generators Product Specifications

- PLC Based

- Up to -60C

- Varies as per model (Customized)

- 95% 99.999%

- Continuous

- Low Maintenance, Energy Efficient, Compact Design

- Yes

- PSA Nitrogen Gas Generator

- Mild Steel / Stainless Steel

- 5 1000 Nm/hr

- 220V 415V, 50 Hz

- 600 3500 kg (Model Specific)

- Pressure Swing Adsorption (PSA)

- Fully Automatic

- 5 7 Bar (Adjustable)

- Industrial/Commercial Nitrogen Production

- Blue / White / Customized

- Customizable

- 3 25 kW

PSA Nitrogen Gas Generators Trade Information

- 1 Unit Per Day

- 1 Week

Product Description

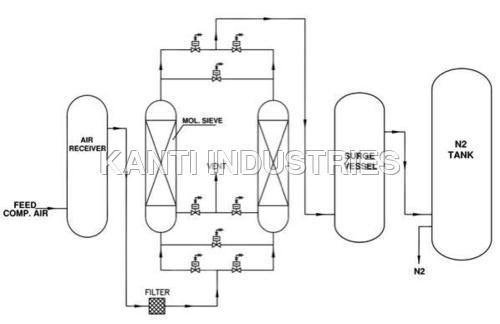

PSA Nitrogen Gas Generator is a high pressure device which is used in many industrial facilities for air to nitrogen production. This machine uses the PSA technology which is also known as Pressure Swing Absorption to separate specific gas molecules from a mixture of air under pressure by absorbing it on absorbent materials such as activated carbon, zeolite etc., PSA Nitrogen Gas Generator helps also helps to improve the quality of nitrogen. It can be used in industries like electronic, tyre, glass manufacturing, metallurgy, petroleum, pharmaceutical, paint, food and beverages. The cylinders used in the generator are made from best grade industrial material which imparts higher strength and make the system leak proof. It provides the economical, Eco-friendly and efficient means to produce nitrogen.

Product details

| Design | Customized |

| Capacity | 10 Nm3/hr to 1500 N m3/hr |

| Condition | New |

| Dew Point | - 50 Degree |

| Brand | Kanti |

| Automatic Grade | Automatic |

Advanced PSA Technology for Pure Nitrogen

This generator uses Pressure Swing Adsorption (PSA) and Carbon Molecular Sieve (CMS) to separate nitrogen from compressed air efficiently. Achieving nitrogen purity as high as 99.999%, it is ideal for sensitive industrial processes. The process is fully automatic, monitored by a digital PLC, ensuring continuous and precise production tailored to the customers needs.

Customizable and Reliable Operation

Customers can specify outlet connection types, flow rates, and installation formats, including standalone, skid-mounted, or containerized units. With a start-up time of just 20-30 minutes and advanced safety interlocks, operation is both swift and secure. The equipment is engineered for a long service life of over 10 years and is robust enough for demanding industrial environments.

Efficient Design with Comprehensive Support

Designed for low maintenance and high energy efficiency, the generator operates quietly (<75 dB) and withstands ambient temperatures of 5C to 45C. Export packaging and after-sales services are available for domestic and international customers. Remote monitoring and digital control panels enhance usability, making it easy to integrate into modern production systems.

FAQs of PSA Nitrogen Gas Generators:

Q: How does the PSA Nitrogen Gas Generator work?

A: The generator operates using Pressure Swing Adsorption (PSA) technology with Carbon Molecular Sieve (CMS) material to adsorb oxygen and other impurities from compressed air, producing high-purity nitrogen continuously. The process is automated and controlled via a PLC system for efficiency and reliability.Q: What installation options are available for this generator?

A: The generator can be installed as a standalone unit, skid-mounted system, or containerized package, depending on site requirements. The dimensions, connections, and configuration can be customized to align with specific customer and space needs.Q: When is it necessary to use oil-free and air-cooled compressors with this system?

A: An oil-free, air-cooled compressor is required to ensure the purest nitrogen output and prevent contamination, which is especially crucial in sensitive industries like pharmaceuticals, electronics, and food processing.Q: Where can these nitrogen generators be used?

A: These generators are suitable for a wide range of industrial and commercial applications, including electronics manufacturing, laser cutting, pharmaceuticals, packaging, food and beverage processing, chemical industries, and more.Q: What process parameters can be monitored or controlled?

A: Parameters such as nitrogen purity, outlet flow, operating pressure (57 Bar), oxygen content at the outlet, and dew point (up to -60C) can be monitored and managed via the PLC-based digital control panel. Optional remote monitoring further enhances operational oversight.Q: How does regular maintenance benefit the nitrogen generators service life?

A: The design emphasizes low maintenance, but routine checks help sustain high efficiency and extend the units service life beyond 10 years. Timely servicing also ensures reliable nitrogen purity and reduces the risk of unexpected downtime.Q: What are the key benefits of using this PSA nitrogen generator?

A: Benefits include customizable capacity and purity, compact and robust design, energy efficiency, low operational noise, quick start-up, flexible installation, digital control, enhanced safety features, and long-term, continuous production with comprehensive after-sales support.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email